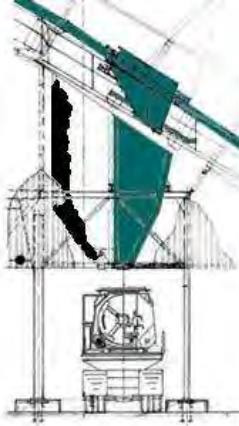

DrumJet

Rotary Drum and Robotic Asphalt Silo Cleaning System

HPC is the West Coast’s high-pressure water applications and water blasting expert, having worked on major projects ranging from the Oroville and Hoover Dams; Hyperion Wastewater Plant; Summit Reservoir in the San Francisco Bay Area; Interstate Highway projects for the California DOT, Hawaii DOT, Nevada DOT and many more.

HPC has recently focused its expertise on the cleaning challenges facing Asphalt Plant rotary drum dryers and mixers, large tanks/silos, and vessels. These units are difficult to clean due to their size, limited access, and internal geometries. HPC utilizes the latest and most technologically advanced robotic high-pressure water equipment in the industry to selectively remove built-up and plugged materials from Asphalt Plant process equipment.

Asphalt Plant HydroPressure Cleaning Applications:

- Rotary Drum Driers & Mixers

- Feed systems

- Asphalt storage silos

- Tower equipment

- Conveyors

- Portable asphalt plants

Key benefits include:

Rotary Drier/Mixer Drum

- High production rate, reduced plant downtime – typically completed in one 8-hour shift

- Eliminate the need to manually clean buildup, protect workers from high-risk, confined space and high-temperature environments

- Quickly removes buildup inside dryer drum, silos, and hoppers

- Breaks up bottlenecks and obstructions, selective removal of adhered asphalt

- Equipment steel is left undamaged, entirely green technology, only water used

Remote Removal of Asphalt build up in Rotary Drums & Silos